Blog

Leveraging the Internet of Things to enable a smart rail infrastructure

Etienne Saclier d'Arquian

19 July 2018

Etienne, networks and telecommunications expert at Thales Ground Transportation Systems, presented how the Internet of Things (IoT) can improve operational and monetary efficiency at the 5th International Railway Summit in Kuala Lumpur.

The railway industry is going through a digital transformation due to recent challenges around increased competition from other transportation methods while coping with limited resources.

Better performance is expected to satisfy the increasing traffic demand in congested cities, leading to optimum utilisation of existing infrastructures. Achieving this within decreasing budgets means better returns on assets, simplified wayside systems and lower maintenance costs. Meanwhile, required efficiency improvements call for more integrated Operation Control Centres, automated with new data-driven functionalities, enabling infrastructure operators to quickly react to incidents. Finally, improving passenger experience is fundamental, while maintaining compliance with safety regulations and cyber security to mitigate new threats created by digitalization.

Rail Infrastructure Managers must at the same time:

• Improve safety conditions and reduce service disruptions,

• Maximize asset availability and increase operations efficiency,

• Optimize the financial return on assets and manage decreasing overall budgets.

This leads to stringent operational requirements for rail infrastructures. Achieving this requires a paradigm shift. To succeed, the industry must develop decision support tools that provide a comprehensive view of the infrastructure and integrate information from increasingly disparate systems. All this leads to smarter maintenance regimes – moving from break and fix to predict and prevent.

This in itself is nothing new. Defence, Aeronautics and Space have developed Health and Usage Monitoring Systems (HUMS) to increase availability and minimize breakdown risks. Applying this model to the railway industry enables predictive maintenance, where failures are anticipated and repaired before service disruption, optimising not only performance but also safety and cost.

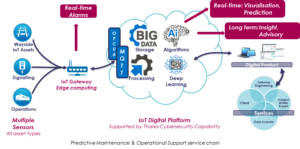

These new capabilities rely on new technologies such as the Industrial IoT, Big Data Analytics and Cloud technologies. Data generated by sensors is collected through versatile networks fit to field conditions, then fed into a cloud infrastructure supported by Big Data Analytics frameworks.Relying on Artificial Intelligence and Deep Learning algorithms, data scientists and subject matter experts combine technical savvy and unparalleled interpretation skills to create insights.

Transforming raw data into knowledge is not easy though. This requires strategic choices like sensors with proper data normalization and formatting, and efficient diagnostic rules. The network and IT architecture should use a good balance of distributed and centralized processing, relying on a scalable IIoT platform, modular enough to accommodate technology evolutions and context-specific operational choices. Cybersecurity is, of course, central to the solution, from sensors up to the application front-ends. These solutions must be scalable with real-time capabilities to enable fast response. A consolidated view of the information also supports immediate monitoring and long-term strategy.

The Industrial IoT model will help railway industry to benefit from predictive maintenance, real-time diagnostics and long-term process optimization. From an integrator’s standpoint, modularity and independence from technology are paramount to ensure future-proofing, and adaptability to diverse Rail Infrastructure manager’s needs.

Then a predictive maintenance solution will significantly improve maintenance costs, downtime and unplanned events. For the maintenance teams, this will also improve work conditions, focussing on high value tasks. Eventually, right-first-time repairs, enabled by accrued anticipation capacities, will minimize time spent on trackside and increase safety conditions.

Category: Blog Competition Digital Revolution passenger rail

Tags: better services innovation passenger rail safety

About the author

Etienne Saclier d’Arquian graduated from Ecole Centrale Paris in 1993, with a Master’s Degree in Engineering, majoring in IT & Networks.

At Thales Ground Transportation Systems, he is in charge of the Networks Product Line that provides connectivity solutions for the whole Integrated Communications and Supervision product range.

He has a 20+ years’ experience in telecommunications solutions design as well as innovation management.

Prior to Thales, he has been in charge of design and operation of global network solutions through various positions with service providers including SITA, Equant, and Reliance Communications.